Ibhola Mill

Incazelo yomkhiqizo

Umshini wokugaya ibhola uqukethe ingxenye yokuphakela, ingxenye yokondla, ingxenye ejikelezayo, ingxenye yokudlulisa (i-reducer, igiya lokuhambisa elincane, imoto, isilawuli sikagesi) njalonjalo. I-shaft engenalutho yenziwa ngensimbi yensimbi, ulwelwesi lungashintshwa, futhi igiya elijikelezayo lenziwe ngamazinyo aginqikayo e-castings. Umgqomo unebhodi yolwelwesi lokuguga, olunokumelana okuhle nokugqoka. Umshini uzinzile futhi unokwethenjelwa.I-Ball mill host host kufaka phakathi isilinda, umzimba wesilinda onolwelwesi oluwusizo olwenziwe ngezinto ezingagqoki ukugqoka, unazo futhi zigcine ujikelezo lwazo lwe-cylinder eziqukethe, eziqhutshwe okuyingxenye, njengemoto, negiya lokushayela, i-pulley, unxantathu, njll.

Mayelana nezingxenye ezibizwa nge-blade, ngokuvamile hhayi izingxenye eziyinhloko, izingxenye ekungeneni kokuphela kokuphakelayo nge-screw yangaphakathi yazo blade evunguza, kungashiwo ezingxenyeni zokuphela kokukhipha okukhipha umlomo ngesikulufa sangaphakathi kungazibiza ngokuthi i-blade blade.

Ngaphezu kwalokho, ezintweni ezisizayo zokuphela kokukhipha, uma kusetshenziswa i-conveyor yokuvunguza, kuzoba nezingxenye ezibizwa ngokuthi ama-spiral blade kulowo mshini, kepha uma kukhulunywa ngokuqinile, akuyona ingxenye yesigayo sebhola. Ibhola lokusila elomile ne-wet grate ibhola lokugaya lingakhethwa ngokuya ngemodi yempahla ne-drainage. Amandla okusindisa ibhola isigayo, i-othomathikhi yokuqondanisa umugqa we-centripetal roller eyindilinga, ukumelana okusebenzayo kuncane, umphumela wokonga amandla uyamangalisa. Ingxenye yomzimba womgqomo womgqomo woqobo ingezwe isilinda sesigaxa, esandisa ivolumu esebenzayo yesigayo futhi yenze ukusatshalaliswa kwendawo emhubheni kunengqondo. Lo mkhiqizo usetshenziswa kabanzi kwinsimbi engenayo i-ayoni, insimbi eyidlanzana, insimu yokuhlomulisa insimbi, imboni yamakhemikhali kanye nomkhakha wezinto zokwakha.

Mayelana nokufakwa

Ball isigayo ukufakwa:

A) uhlelo lokufaka lwakhiwe ngokuya ngobunjiniyela obuyisisekelo bomsebenzisi futhi kufanele lufakwe ohlangothini, endaweni nasendaweni yomdwebo;

B) indiza engezansi ye-fuselage kufanele iqine, futhi ukundiza kwendiza engezansi yesilinda akuyona enkulu kune-1.5 / 1000 ngemuva kokulungiswa okuvundlile.

Faka:

A) khipha okokusebenza esisekelweni semishini yokufaka, ikakhulukazi udonga lwangaphakathi lomgodi akufanele lube nothuli, uwoyela, amanzi nolunye uketshezi;

B) ngemuva kokukhipha amabhokisi okupakisha, injini enkulu izoyiswa endaweni yokufaka enezindawo ezifanele zokuphakamisa (i-crane / forklift);

C) beka okokusebenza endaweni efanele, izimbobo ezigxilisa ibhawodi, futhi "izinyawo eziphilayo" zebhande elingahleliwe zizofakwa ku-chassis yohlaka ngemuva kokufakwa ku-chassis yohlaka, bese kungenziwa ukubamba okwesibili;

D) ngemuva kokufakwa kwamahora angama-24 amandla kasimende, ingasetshenziselwa ukuqinisa umshini wokuhlola ukulayishwa kwamantongomane;

E) ukufinyelela emandleni;

F) ukuhlolwa kokufakwa nokulungiswa kokungahambi kahle;

G) amakhabethe kagesi abekwe egumbini lenjini elisizayo ngaphandle kwesidingo sokufaka phansi.

Umsebenzi wokuhlola:

Ukufakwa kwesigayo seBall kuqedile, ukuhlolwa, kungaba yinto engenalutho yokuhlolwa, ukukhishwa kwebhola lokugaya ngabasebenza ngebhola abanekhono kufanele babhekele, isigayo sebhola futhi bathobele ngokuqinile izinqubo zokusebenza kokuphepha.

(1) isikhathi sokusebenza kokungenzi lutho ngeke sibe ngaphansi kwamahora ayi-12-24, futhi izinkinga ezisebenzayo zizoxazululwa ngesikhathi.

(2) ukusebenza kokungenzi lutho kokuyalela ukuhlolwa okujwayelekile komthwalo, kungenziwa lapho ukuhlolwa komthwalo kuqhutshwa kuzo zonke izigaba, ukusebenza komthwalo kufanele kwenziwe ngokuya ngesimo sokukhishwa kokuphakelayo, gwema ibhola lokugaya elingadingekile kanye ne-cylinder liner nomonakalo.

A) engeza izinto ezifanele kanye ne-1/3 yamabhola wensimbi (isisindo esiphezulu sebhola lesigayo) ukuzama amahora ayi-12 kuye kwangama-24.

B) engeza kuze kufike ku-2/3 wenani lamabhola wensimbi ongasebenza amahora angama-24 kuye kwangama-48.

C) ngokuya ngezimo zokukhishwa kwebhola lokugaya ibhola, ukukhiqizwa kwemikhiqizo efanelekile, ngokubhekisele kuhlobo olufanayo lomshini wokugaya ibhola uqobo, inquma inani lokulayisha ibhola lomshini wokugaya ibhola, isikhathi esingaphansi kwamahora angama-72 sokuhlolwa kokuhlolwa.

(3) ukukhuphuka komthwalo ongenhla nobude besikhathi sokuhlolwa kunqunywa ngokuya ngezimo ezisebenzayo zegiye likamagiya osayizi kanye negiya lokunciphisa (ukukhuphuka kwamazinga okushisa, umsindo, ukuxhumana kwamazinyo, njll.). Ngaphambi kokuba ukunemba kokuxhumana kwendawo yamazinyo kungahlangabezani nezimfuneko zokuklama, ngeke kusebenze ngokugcwele.

(4) uhlelo lokupholisa nokugcoba kufanele lusebenze ngokujwayelekile ekusebenzeni kokuhlolwa, futhi izinga lokushisa lokuthwala okuyinhloko, ukuhanjiswa kokuthwala kanye nesinciphisi kufanele kube okujwayelekile.

(5) ngemuva kokulayisha u-2/3 wesivivinyo sebhola lensimbi amahora angama-24 kuye kwangama-48, hlola futhi uqinise wonke amabhawodi.

(6) ukusebenza kwecala kufanele kuqoshwe ngokucophelela.

Ukuxuba, ukugaya, ukugaya ibhola kusetshenziselwa izinto zokwenziwa nge-ceramic kuyisidingo esidingekayo sokukhiqiza izinhlobo ezahlukahlukene zemikhiqizo ye-ceramic, umshini USEBENZISA ukucindezela kokuhlangana, unciphise ukuqala kwamanje, isakhiwo sawo sihlukaniswe saba yinto ehlanganisiwe futhi ehlukanisiwe. Nge-v-belt drive, isiteji esisodwa noma ukwehla kabili, ifakwe imoto ezimele yamandla amancane.

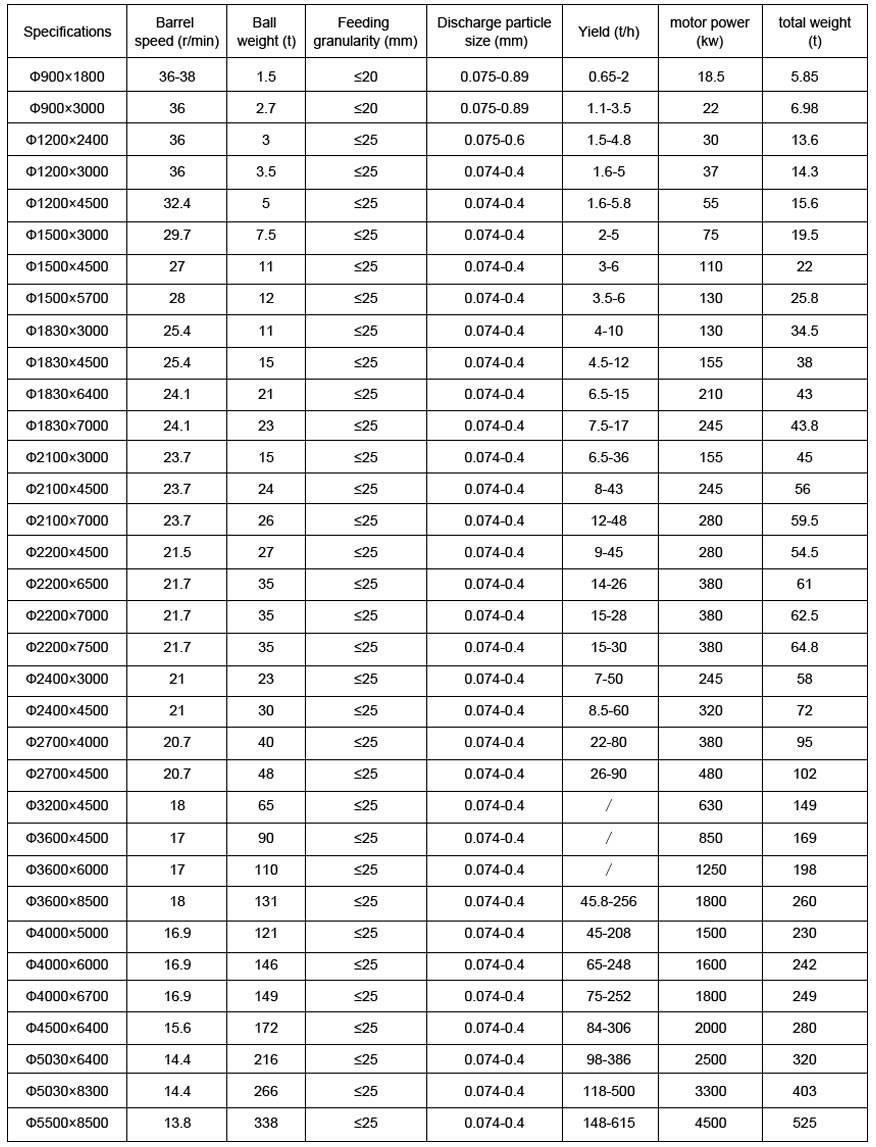

Idatha yokusebenza